UV imposition

- Commodity name: UV imposition

- Commodity ID: 02

Classification:

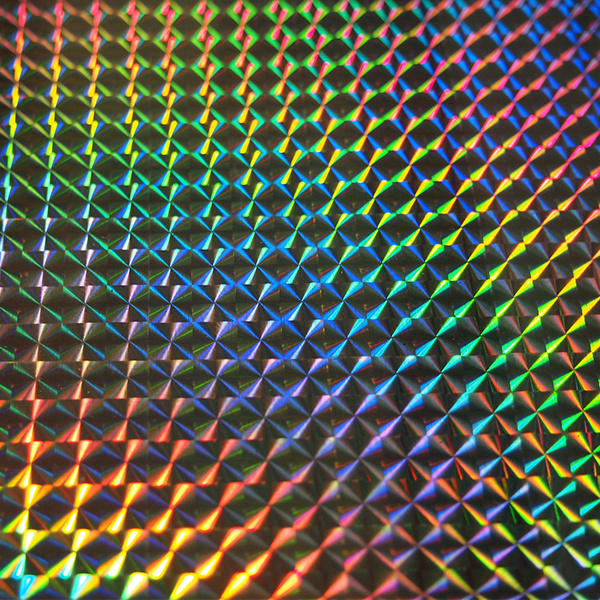

At present, lithography anti-counterfeiting trademarks and anti-counterfeiting packaging are becoming more and more popular, especially the micro-structures of deep grooves such as cat's eyes and microlenses. Many companies want to use this technology to package their products. The master of reflective anti-counterfeiting wrapping paper for hot stamping needs to be spliced with a grating of small-size units to form a large-size master, or several patterns are spliced on one master. In view of the above problems, the Mars era research and development launched UV holographic imposition service, will be different or the same micro-nano structure master unit combination and positioning, to form a new template layout of the master production.

You can email us: zdonghai@yahoo.com

INQUIRY IMMEDIATELYProduct Details

At present, lithography anti-counterfeiting trademarks and anti-counterfeiting packaging are becoming more and more popular, especially the micro-structures of deep grooves such as cat's eyes and microlenses. Many companies want to use this technology to package their products. The master of reflective anti-counterfeiting wrapping paper for hot stamping needs to be spliced with a grating of small-size units to form a large-size master, or several patterns are spliced on one master. In view of the above problems, the Mars era research and development launched UV holographic imposition service, will be different or the same micro-nano structure master unit combination and positioning, to form a new template layout of the master production.

The Mars era will use a computer program-controlled platform positioning device to expand the area of the micro-nano structure unit version, different graphic combinations, and multi-printing unit version by nano-imprinting method. The base line and positioning mark of broken sheet and slitting can be added during imposition. The positioning mark shall meet the requirements for photoelectric automatic identification of post-process equipment.

The working principle of UV imposition (plate assembly machine) is to coat and roll UV glue through a transparent unit master capable of penetrating ultraviolet rays. After the transparent unit mold and plastic plate are bonded, the UV glue is caused to cross-link and cure by exposure of ultraviolet light source, and the embossed micro-nano structure stripes on the transparent unit master are transferred to a large-area plate. The XY platform is included through servo motion control, unit attitude positioning calibration, unit lifting, rolling movement, dispensing and other precision automatic control to complete the imposition. The advantage of this method is that the micro-nano groove shape replication accuracy is high, the unit lithography master plate area is large, the seam quality is high, especially suitable for large-area decorative texture splicing plate expansion.

UV Recombination Machine

Laser holographic UV imposition equipment

High precision imposition environment control system, effectively improve the success rate of imposition.

The use of integrated design with the group version of the material pretreatment system, to achieve a dual-use.

PC control mode, improve graphics control editing flexibility, convenience.

Class 100000 dust-free workshop environment to improve the first pass rate of imposition.

Unit area: 200*260mm2

Maximum imposition area up to 1000*2000mm2

Including but not limited to packaging anti-counterfeiting holographic positioning, metal relief, Fresnel lens, naked eye 3D, seamless shading and other micro-nano structure replication and imposition.